Opening a THCa retail operation or hemp shop requires navigating one of the most critical business challenges: inventory procurement. Your product sourcing strategy directly impacts profit margins, competitive pricing, customer satisfaction, and ultimately whether your business succeeds or fails. Stock too expensive and you can’t compete on price. Buy cheap, low-quality product and you lose customers who won’t return. The challenge is finding the sweet spot—sourcing cheap thca flower that maintains quality standards while delivering margins that sustain your business.

The THCa wholesale market offers numerous pathways to affordable inventory, from bulk purchasing and smalls to direct-from-cultivator relationships and strategic timing around harvest cycles. However, many new retailers make costly mistakes: overpaying middlemen, purchasing without verifying quality, failing to negotiate terms, or missing seasonal opportunities that could reduce costs by 30-40%. Understanding the complete landscape of wholesale procurement separates profitable operations from those struggling with thin margins.

This comprehensive guide reveals exactly how to stock your THCa retail operation cost-effectively while maintaining quality. You’ll learn where to find the cheapest thca ounce pricing without sacrificing standards, how to leverage smalls and bulk deals for maximum margins, when to time purchases for optimal pricing, and proven negotiation strategies with suppliers. Whether you’re launching a new shop or optimizing an existing operation, these tactics will reduce your cost of goods sold and improve profitability.

Understanding Wholesale THCa Pricing Structure

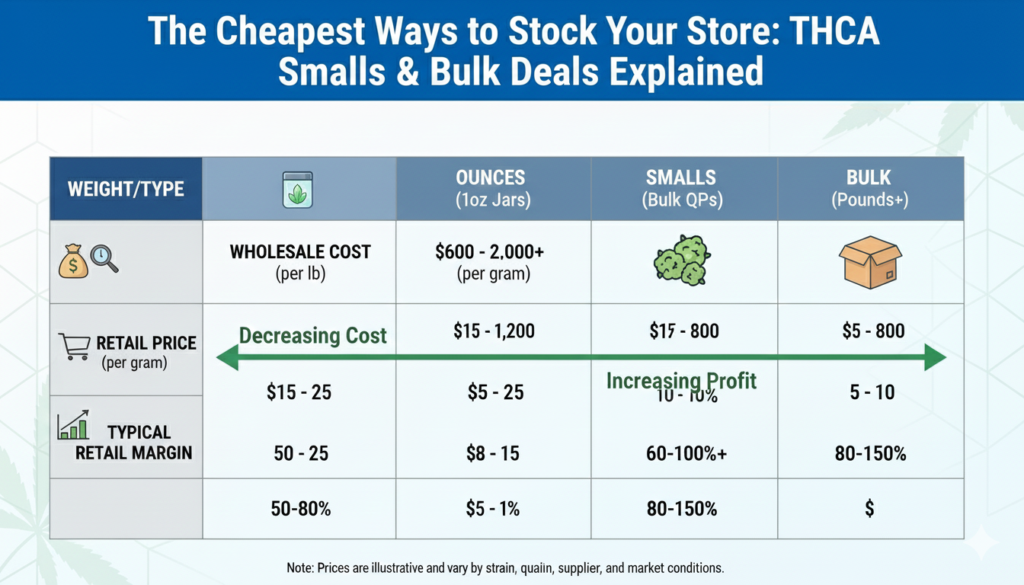

Before diving into specific sourcing strategies, understanding how wholesale pricing works empowers better purchasing decisions and realistic margin expectations.

The Distribution Chain and Markup Points

Cultivator to Distributor: 10-30% markup depending on volume and relationship

Distributor to Retailer: 20-40% markup for handling, storage, and logistics

Retailer to Consumer: 50-100%+ markup covering overhead, labor, and profit

Each intermediary layer adds costs. Eliminating steps by purchasing direct from cultivators or consolidating through fewer distributors improves your margins substantially.

Wholesale Price Ranges by Quality Tier

Budget Wholesale ($200-400/lb | $12-25/oz equivalent) Outdoor flower, older inventory, B-grade smalls. THCa 12-20%. Suitable for budget retail positioning, edible production, or value-tier offerings.

Mid-Tier Wholesale ($400-800/lb | $25-50/oz equivalent) Quality smalls from indoor operations, greenhouse full-sized, solid genetics. THCa 18-25%. The sweet spot for most retail operations balancing quality and affordability.

Premium Wholesale ($800-1,400/lb | $50-87/oz equivalent) Indoor full-sized, exotic genetics, top-shelf smalls. THCa 24-30%+. For retailers targeting connoisseur markets or building premium brand positioning.

Ultra-Premium ($1,400-2,000+/lb | $87-125+/oz equivalent) Limited-run exotics, award-winning genetics, craft cultivation. Reserved for specialty retailers or flagship products.

Calculating Your Retail Margins

Example calculation:

- Wholesale cost: $600/lb ($37.50/oz)

- Retail price: $90/oz

- Gross margin: $52.50/oz (58%)

- Monthly volume: 80 oz

- Gross profit: $4,200/month

Understanding this math helps you evaluate whether thca flower deals actually translate to sustainable margins after accounting for overhead, labor, shrinkage, and other operational costs.

Strategy 1: Direct-from-Cultivator Sourcing

Eliminating distributors by purchasing directly from hemp farms represents the single most effective way to reduce inventory costs.

Benefits of Direct Purchasing

Price advantages: 20-35% lower than distributor pricing by eliminating middleman markup. Quality control: Direct relationship with growers means better visibility into cultivation practices. Customization: Ability to request specific strains, trim levels, or packaging. Consistency: Building relationships ensures reliable supply and consistent quality batch-to-batch.

Finding Legitimate Cultivators

State hemp registries: Most states publish licensed cultivator lists—start here for verified, compliant operations.

Industry trade shows: Hemp and cannabis expos connect retailers with multiple cultivators, allowing relationship building and product sampling.

Online directories: Platforms like Leafly Business, Weedmaps Wholesale, and specialized hemp directories aggregate cultivator information.

Regional farming communities: In hemp-friendly states (Oregon, Colorado, North Carolina, Tennessee), local farming communities often have multiple cultivators seeking retail partners.

Vetting Cultivator Partners

Before committing to direct purchasing, verify:

Licensing and compliance: Confirm active hemp licenses and compliance history. Cultivation practices: Understand growing methods (indoor/outdoor/greenhouse), organic certifications, pest management. Testing protocols: Verify they conduct batch-specific COA testing through accredited labs. Minimum order quantities: Many cultivators require 5-10 lb minimums for direct sales. Payment terms: Understand if they offer net-30/60 terms or require prepayment. Consistency and reliability: Request references from other retail customers.

Negotiating Direct Deals

Volume commitments: Offering consistent monthly/quarterly purchasing often unlocks 10-15% additional discounts.

Advance payment: Some cultivators discount 5-10% for payment 30-60 days before harvest.

Mixed variety: Negotiate pound-level pricing while splitting across 4-8 strains for inventory variety.

Long-term contracts: Annual agreements with minimum purchase commitments can secure best pricing and supply priority.

Strategy 2: Maximizing Value with Smalls and Popcorn Buds

Cheap thca smalls represent exceptional value for retailers who understand that bud size doesn’t determine quality—genetics and cultivation do.

The Smalls Value Proposition

Quality smalls from premium cultivators contain identical THCa percentages and terpene profiles to full-sized flowers but wholesale at 30-50% discounts simply due to aesthetics.

Wholesale pricing comparison:

- Full-sized premium indoor: $1,200/lb ($75/oz)

- Premium indoor smalls: $700/lb ($44/oz)

- Savings: $500/lb (42%)

This pricing differential creates significant retail margin opportunities.

Retail Positioning for Smalls

Budget tier offerings: Retail smalls at $60-80/oz where full-sized costs $100-120/oz, capturing price-conscious customers while maintaining healthy margins.

Pre-roll production: Smalls excel for in-house pre-roll manufacturing—you’re grinding anyway, making bud size irrelevant.

Value ounce specials: Feature rotating smalls strains as weekly/monthly deals to drive traffic and customer loyalty.

Mixed ounce options: Let customers build custom ounces from multiple smalls strains at value pricing.

Sourcing Quality Smalls

Verify genetics: Ensure smalls come from the same premium grows producing the cultivator’s top-shelf products.

Request COAs: Cannabinoid and terpene testing should approximate full-sized offerings.

Sample before committing: Always test product quality before placing large orders.

Establish quality baselines: Set minimum standards for trichome coverage, moisture content, and aroma even for smalls.

Build relationships: Cultivators appreciate retailers who value smalls, often offering first access to batches before other buyers.

Common Smalls Pitfalls to Avoid

Not all smalls are equal: Some sellers label genuinely poor-quality outdoor flower as “smalls” to move problematic inventory. Verify source and quality.

Excessive stem content: True smalls should maintain good flower-to-stem ratio. Reject batches with excessive stems.

Outdated inventory: Ensure smalls aren’t simply old full-sized inventory broken down after sitting too long.

Unclear sourcing: If suppliers can’t identify which premium grows their smalls originated from, question legitimacy.

Strategy 3: Bulk Purchasing and Weight Break Optimization

Scaling up order sizes unlocks dramatic per-unit savings that directly translate to improved margins or competitive retail pricing.

Understanding Bulk Pricing Tiers

5-10 lb orders: Typically 10-15% below single-pound pricing

10-25 lb orders: Usually 20-30% below single-pound pricing

25-50 lb orders: Often 30-40% below single-pound pricing

50+ lb orders: Custom negotiated pricing, can reach 40-50% below single-pound

Example:

- Single pound: $700

- 10-pound order: $600/lb (14% savings = $1,000 total)

- 25-pound order: $525/lb (25% savings = $4,375 total)

Managing Inventory and Storage

Bulk purchasing requires proper storage infrastructure:

Climate control: Maintain 60-70°F with 55-62% relative humidity to prevent degradation.

Organization systems: Label and track batches by strain, harvest date, and COA information.

FIFO rotation: First-in, first-out inventory management ensures older stock moves before freshness degrades.

Proper containers: Invest in quality airtight storage—mason jars for display, larger containers or vacuum-sealed bags for backstock.

Security measures: Adequate security systems protect valuable inventory from theft.

Calculating Optimal Order Quantities

Consider these factors when determining bulk order sizes:

Sales velocity: Order 2-3 months of inventory based on actual sales data to balance savings against freshness.

Storage capacity: Don’t exceed your ability to properly store product.

Capital requirements: Larger orders tie up more cash—ensure cash flow supports bulk purchasing.

Product variety: Balance bulk savings against customer demand for strain variety.

Supplier minimums: Many wholesalers require 5-10 lb minimums—plan accordingly.

Mixed Bulk Orders

Smart retailers negotiate pound-level pricing while splitting across multiple strains:

Example: Purchase 10 lbs at $600/lb pricing, split as:

- 3 lbs premium indoor Strain A

- 3 lbs exotic Strain B smalls

- 4 lbs mid-tier outdoor Strain C

This maintains inventory variety while capturing bulk discounts.

Strategy 4: Strategic Timing and Seasonal Opportunities

The agricultural cycles governing hemp cultivation create predictable pricing patterns throughout the year.

Harvest Season Purchasing (September-November)

Outdoor and greenhouse harvests peak in fall, flooding markets with fresh flower and creating substantial price reductions.

Typical harvest season savings: 20-35% below off-season pricing

Opportunity: Stock 3-6 months inventory at optimal pricing

Consideration: Requires storage capacity and capital to take advantage

Strategy: Pre-negotiate harvest season deals in summer before supply hits market

Post-Harvest Clearance (December-February)

As fresh harvest product saturates inventory, cultivators clear older stock aggressively.

Pricing opportunity: 30-50% discounts on perfectly good 6-12 month old flower

Quality consideration: Verify proper storage—well-maintained inventory retains quality

Retail positioning: Position as value offerings or use for edible production

Off-Season Dynamics (March-August)

Supply tightens as harvest inventory depletes, typically driving prices up 15-25%.

Strategy: Avoid large purchases during peak pricing

Alternative: Establish relationships during harvest season for preferential off-season access

Holiday and Promotional Periods

Key retail events create wholesale opportunities:

4/20 (April): Distributors and cultivators run promotions supporting retail sales events

Black Friday/Cyber Monday: Wholesale deals mirror consumer retail patterns

New Year: Clearance of previous year’s inventory

Strategy: Plan 30-60 days ahead, pre-negotiate wholesale support for retail promotions

Strategy 5: Building Strategic Supplier Relationships

Long-term supplier partnerships unlock pricing, terms, and priority access unavailable to transactional buyers.

Relationship-Building Tactics

Consistent ordering: Regular, predictable purchasing makes you a valued customer worth offering better terms.

Clear communication: Professional, responsive communication builds trust and goodwill.

Prompt payment: Paying invoices on-time or early establishes reliability.

Feedback sharing: Providing sales data and customer feedback helps suppliers understand market demand.

Flexibility: Being flexible on strain selection when suppliers have excess inventory creates mutual benefit.

Negotiating Better Terms

Payment terms: Request net-30 or net-60 versus prepayment to improve cash flow.

Exclusive arrangements: Some retailers negotiate territorial exclusivity on specific strains in exchange for minimum volume commitments.

First-right access: Established relationships often grant first access to new genetics or limited batches.

Custom processing: Request specific trim levels, packaging, or other customizations.

Returns and credits: Negotiate policies addressing legitimate quality issues.

Multi-Supplier Strategy

Primary supplier (60-70% of volume): Deepest relationship, best terms, consistent core inventory

Secondary suppliers (20-30%): Provides variety, backup supply, competitive pressure

Specialty suppliers (10%): Sources for unique exotics or specific customer requests

This approach balances relationship benefits with supply chain resilience and competitive pricing.

Quality Control: Never Sacrifice Safety for Savings

Finding the cheapest thca ounce or thca flower lowest price becomes counterproductive if quality issues damage reputation or create legal problems.

Non-Negotiable Quality Standards

Certificate of Analysis (COA): Every batch must include recent third-party lab testing from accredited facilities.

Safety screening: Verify absence of pesticides, heavy metals, mycotoxins, and microbials regardless of price.

Legal compliance: Confirm delta-9 THC remains under 0.3% and hemp sourcing is properly licensed.

Physical quality: Maintain minimum standards for trichome coverage, cure quality, moisture content, and aroma.

Red Flags Indicating Problem Product

Suspiciously low pricing: If deals seem too good to be true (budget flower under $200/lb), investigate thoroughly.

No COAs or generic testing: Batch-specific, recent COAs are mandatory—reject product without them.

Evasive suppliers: Legitimate wholesalers transparently answer questions about cultivation, testing, and sourcing.

Minimal online presence: Research potential suppliers—established operations have traceable histories.

High-pressure tactics: Reputable suppliers don’t pressure immediate decisions without proper due diligence.

Sample Testing Protocol

Before committing to large orders:

- Request samples (1-2 oz minimum)

- Verify COAs match sample batches

- Physical inspection for quality indicators

- Customer test group gathers feedback on effects and satisfaction

- Small initial order (1-2 lbs) before scaling

- Monitor customer feedback on retail sales before reordering

Conclusion: Building a Sustainable Procurement Strategy

Stocking your THCa retail operation cost-effectively requires strategic thinking beyond simply finding the cheapest prices. The most successful retailers optimize across multiple dimensions: direct cultivator relationships eliminating middleman markups, strategic use of smalls and popcorn buds capturing 30-50% discounts, bulk purchasing unlocking volume discounts, seasonal timing leveraging harvest cycles, and supplier relationship development accessing preferential terms.

Key implementation steps:

- Establish direct cultivator relationships for 20-35% savings

- Build smalls inventory programs capturing margin opportunities

- Calculate optimal bulk order quantities balancing savings and storage

- Plan purchasing calendar around harvest and clearance cycles

- Maintain quality standards regardless of pricing pressure

The retailers thriving in competitive THCa markets source strategically rather than opportunistically. They understand that the cheapest thca flower that meets quality standards beats marginally cheaper options with quality concerns. They build supplier relationships that create long-term advantages versus constantly chasing lowest one-time pricing.

Ready to optimize your procurement? Start by auditing your current suppliers, calculating true delivered costs including quality issues, and identifying 2-3 direct cultivator relationships to develop. What procurement strategies have worked for your operation? Share insights in the comments.